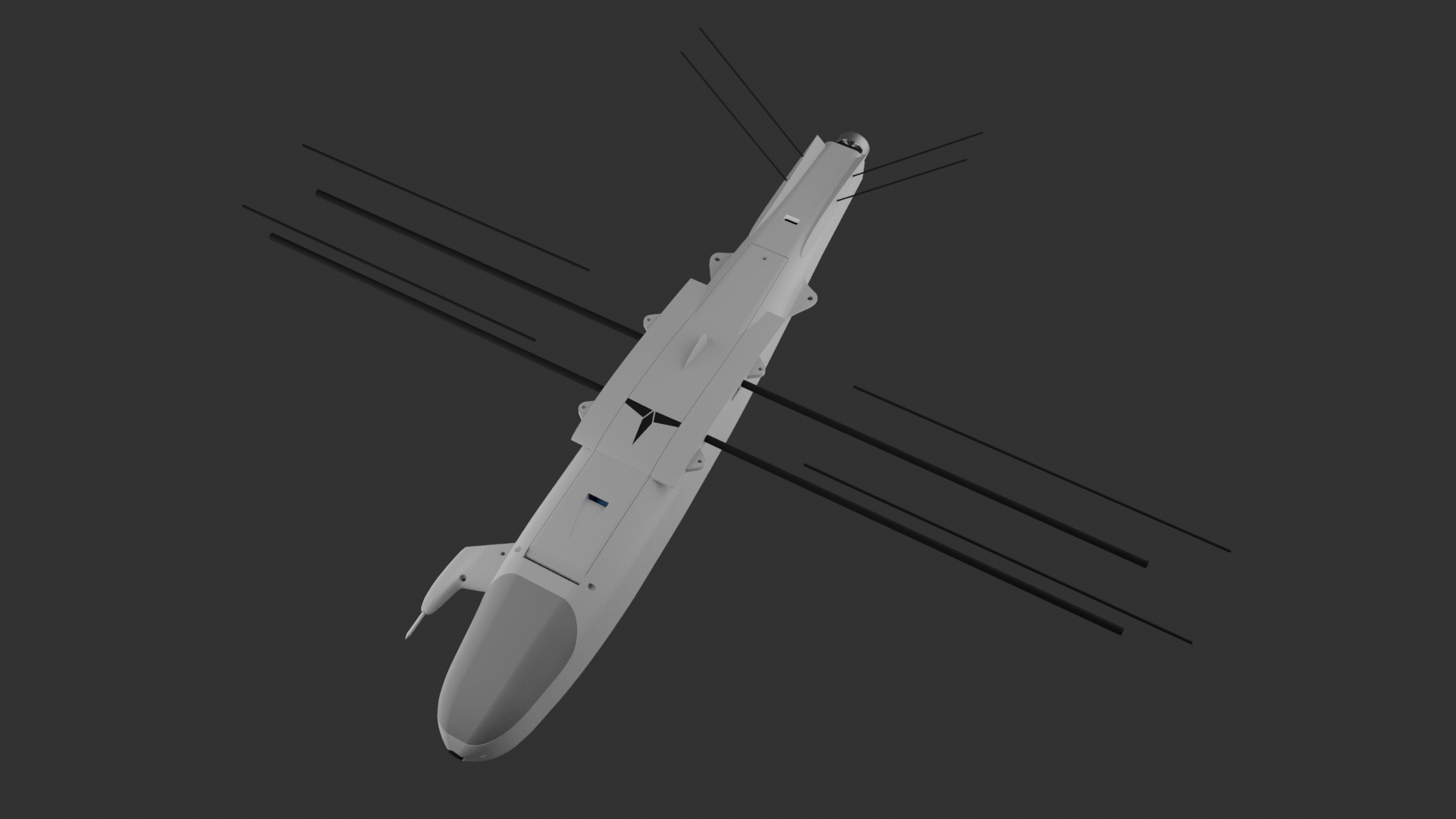

Titan Talon Classic

The Titan Talon is known to be the world’s first 3D printable UAV focused on maximizing range, efficiency, and endurance. The original Titan Talon was the first model we publicly released as our gift to the community and we are happy to now present the Titan Talon Classic - our highest bang for buck model with a slew of upgrades to the original:

40mm more wingspan

Removable canopy

Expanded hatch rotation angle - such that it stays open

Flat fuselage floor with integrated battery strap slot

Integrated support built into the fuselage floor

All new vtail with serviceable servos

Updated attachments for control surface linkages

Flush mounted aileron servos

Optional airspeed sensor mount + optional antenna mounts

More streamlined motor mount

Significantly improved rigidity of the wing and vtail

Fully supportless printing

Additional features: Removable wings, large inner space for batteries, efficiency of 62mah/km (on 4S) which is 25% more efficient than most foam Mini Talon builds.

Max range: 300km+ | Max flight time: 4.5 hours

Titan Talon Classic

The Titan Talon is known to be the world’s first 3D printable UAV focused on maximizing range, efficiency, and endurance. The original Titan Talon was the first model we publicly released as our gift to the community and we are happy to now present the Titan Talon Classic - our highest bang for buck model with a slew of upgrades to the original:

40mm more wingspan

Removable canopy

Expanded hatch rotation angle - such that it stays open

Flat fuselage floor with integrated battery strap slot

Integrated support built into the fuselage floor

All new vtail with serviceable servos

Updated attachments for control surface linkages

Flush mounted aileron servos

Optional airspeed sensor mount + optional antenna mounts

More streamlined motor mount

Significantly improved rigidity of the wing and vtail

Fully supportless printing

Additional features: Removable wings, large inner space for batteries, efficiency of 62mah/km (on 4S) which is 25% more efficient than most foam Mini Talon builds.

Max range: 300km+ | Max flight time: 4.5 hours

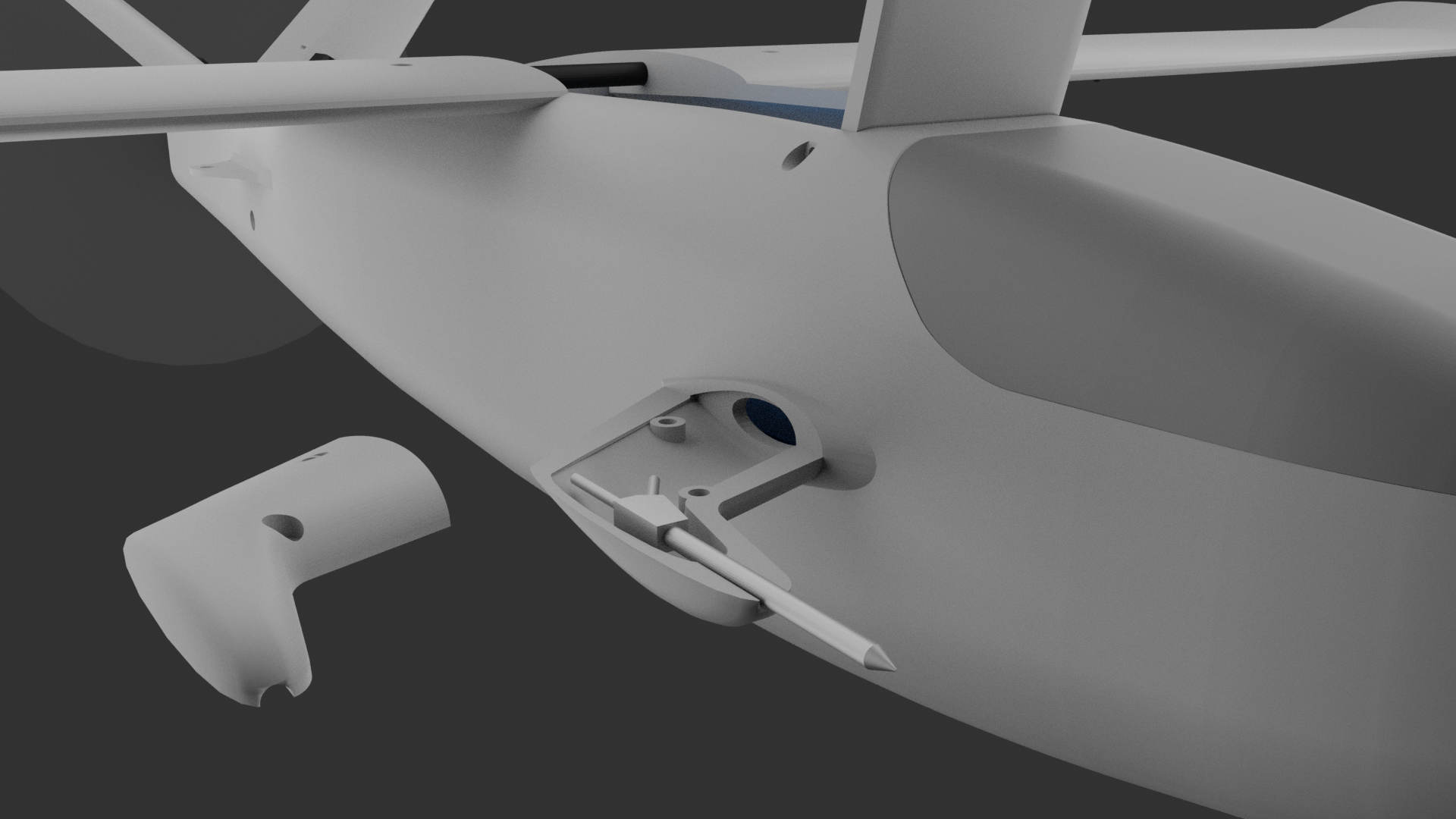

The removable front canopy allows for streamlining the Talon when a pan/tilt setup is not used. An optional nose without the camera is included as well

Shown above: One of the fuselage pieces highlighting the flat floor as well as integrated battery strap slot. The floor also has hard mounting points built in (put threaded inserts in them) to mount electronics and other components

The hinged hatch will now stay open on its own since it can rotate up to 105 degrees, allowing for easier battery insertion and access to internal components

Upgraded dual 8x1000mm main spars greatly increase the rigidity of the wing. Longer 2x220mm spars in the vtail also increase rigidity in the tail

The vtail can now be printed fully supportless, and features larger tailerons as well as serviceable servo mounting

The optional airspeed sensor mounting is simple, low drag, and lightweight. The bottom half of the housing must be glued to the fuselage, while the top half can be screwed on. The housing fits both the pitot tube as well as the sensor PCB, allowing for a non-permanent install with only wires exiting the housing and no tubes

Pictured above without airspeed sensor or antenna mounts if neither are desired (all options included)

Materials

Print using prefoamed LWPLA (this one) and you will need the following parts:

(2) 8x1000mm hollow (6mm ID) carbon tubes (main wing spars)

(4) 3x400mm carbon rods (aileron hinge and wingtip support)

(4) 2x220mm carbon rods (taileron hinge and vtail)

A bunch of m3 threaded inserts <= 6mm in height

Recommend using Emax es08maii servos for wire clearance

6x3mm magnets for the canopy

Medium CA glue

Polycarbonate or other high-temp filament for the motor mount

220x220x250 minimum size print bed (Ender 3)

Tips & Tricks

Recommended electronics:

Video: RMRC or Matek 1.2ghz VTX - or 5.8 analog/digital

Control link: Dragonlink / TBS crossfire / ELRS

Motor: 4108 620kv or similar

Prop: 12x10 or 13x8 or similar folding props

Battery: 4S6P 21000mah or similar

Flight controller running Ardupilot (such as Matek F405-WTE)

Matek M8Q-5883 GPS

Blheli 35a ESC (lighter the better)

19x19 FPV camera (digital or analog)

Emax ES08maii servos (for wire clearance)

Print settings:

Single wall

4 top/bottom layers

0.3mm layer height

3% cubic subdivision infill

Avoid warping by using a glass bed + glue stick or PEI sheet

NO supports needed!

Set horizontal hole expansion setting correctly (try 0.25) for spar fitment

Print the motor mount in Polycarbonate or PETG with 2 walls and 15% infill

Other recommendations:

Configure flaperons (they work great)

Apply 1-2mm of reflex (up elevator) for best stability

Autotune or bump PIDs significantly for snappy performance

Aim for an AUW between 1.5kg and 3kg

Aim for CG as close to the wing marking as possible

Give it a nice run up + hard throw into the wind on launch

Reinforcement:

Apply rubberized tape / duct tape to the bottom of the fuselage for protection against harsh landings

Use a rubberized strap (in the slots in the fuselage) + velcro for securing the battery

Apply epoxy to the motor mount area to prevent prop snag damage during landing

Additional Info

Wingspan: 1436mm

Wing area: 2967cm^2

Max takeoff weight: 3.3kg

Licensed under the Creative Commons - Attribution - Non-Commercial license.