Titan Comet

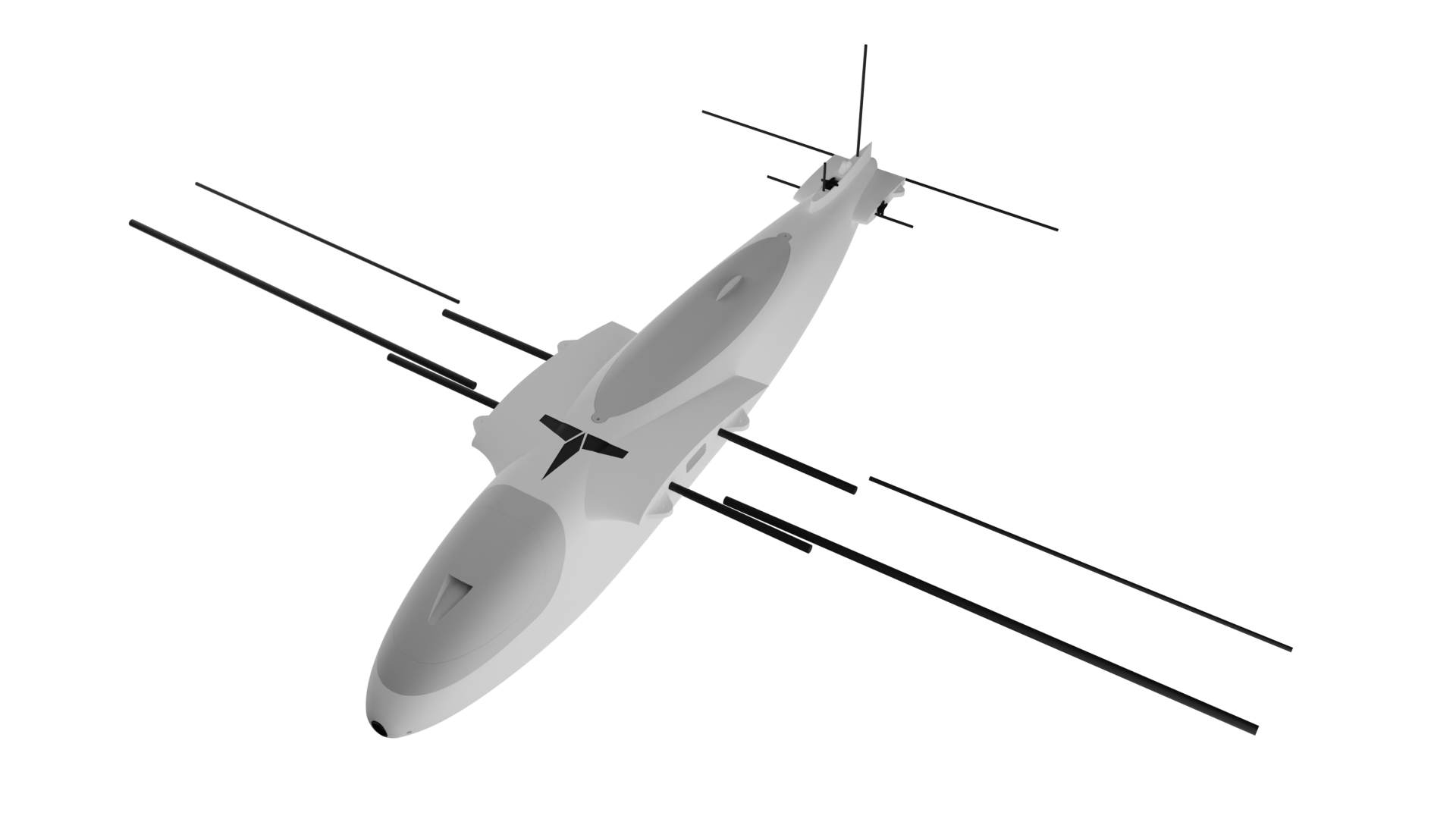

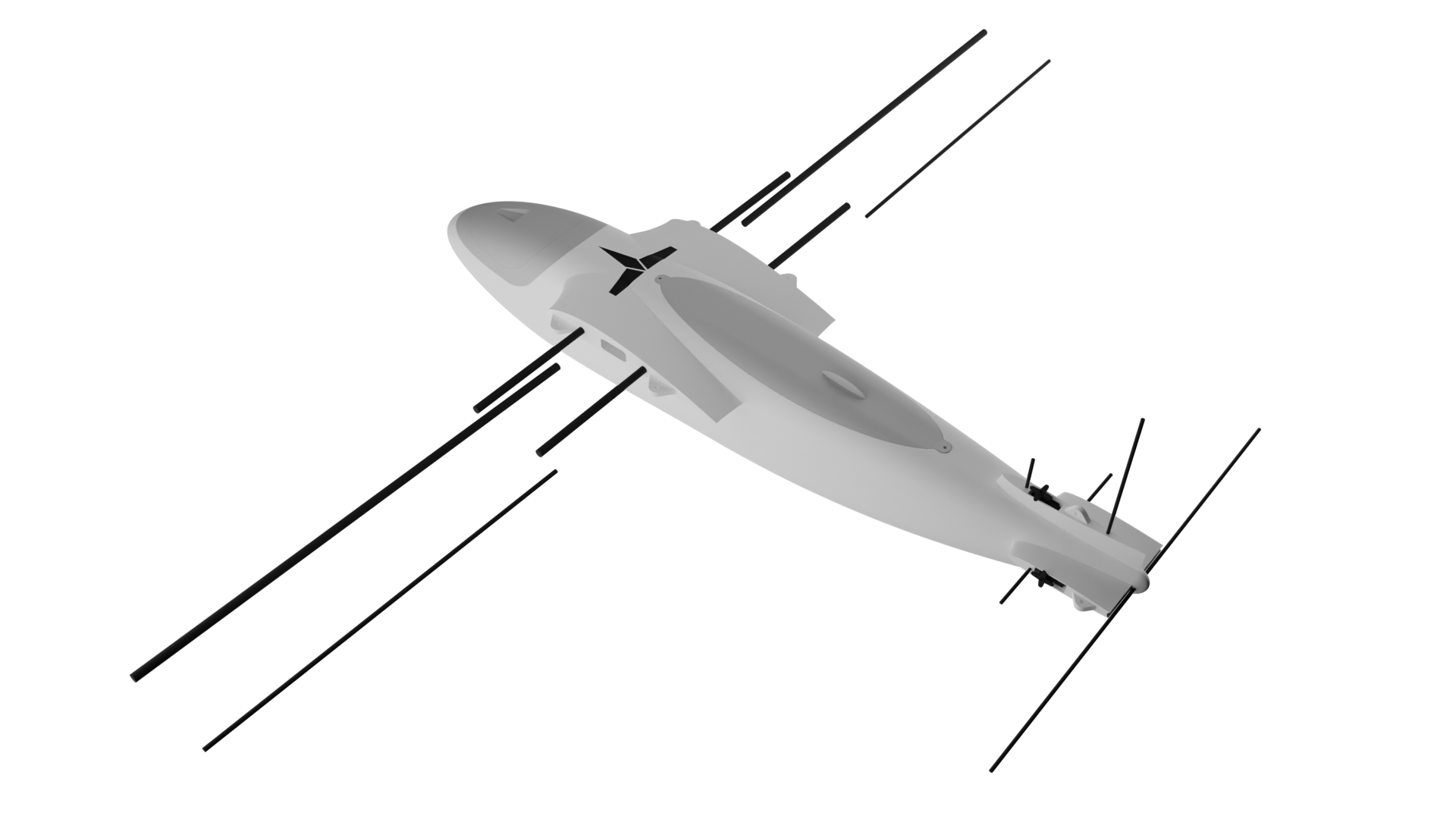

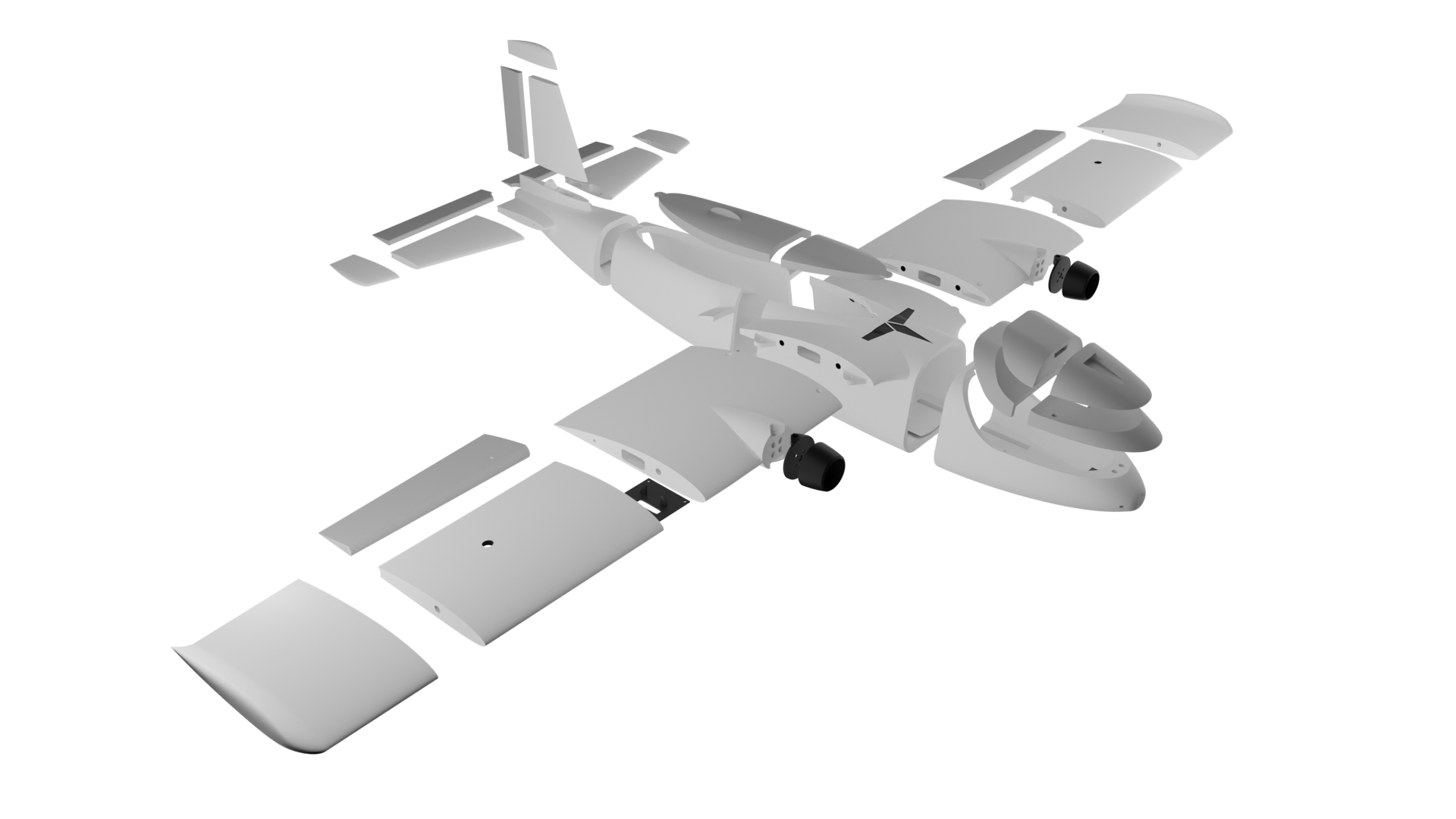

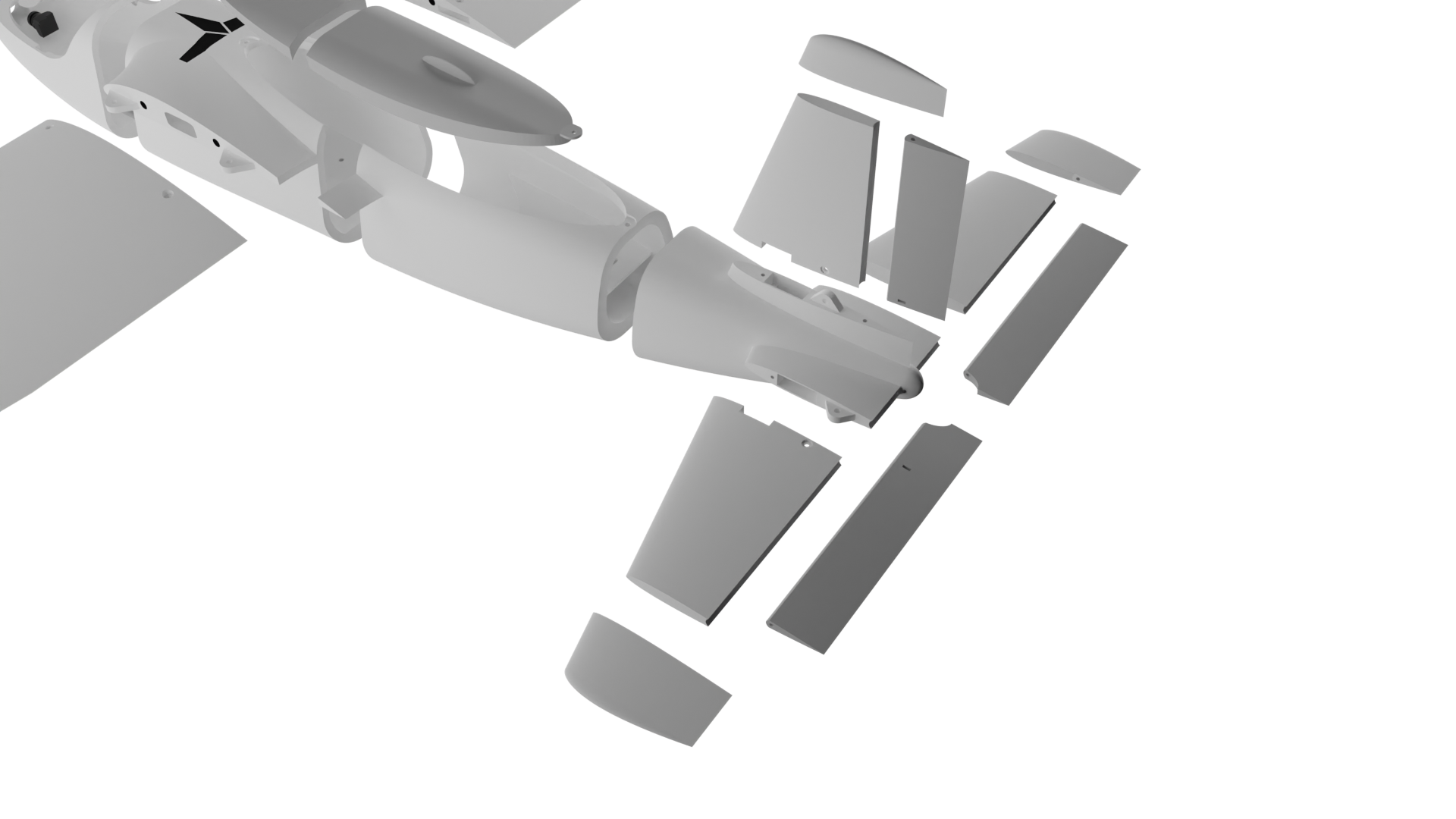

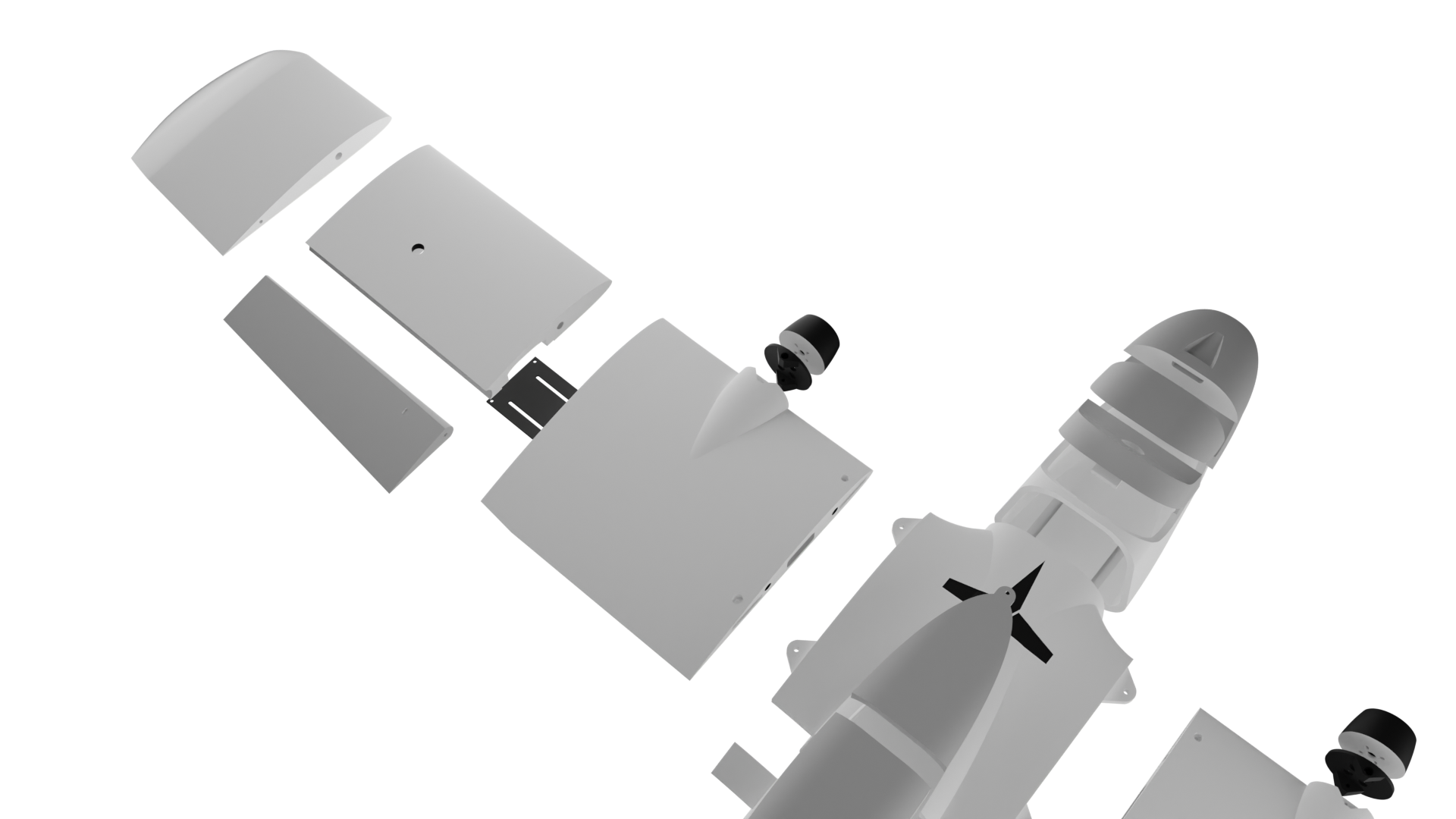

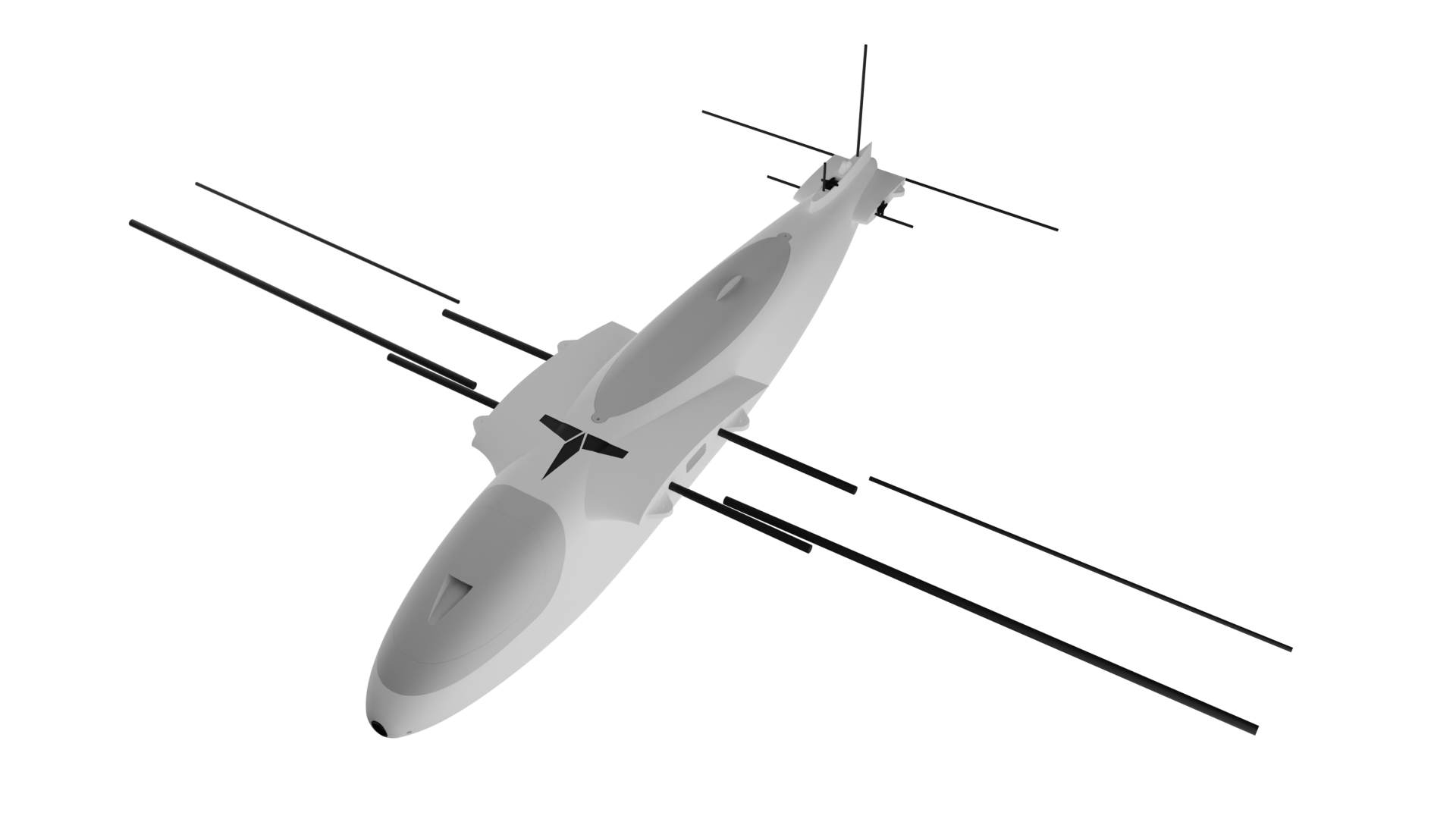

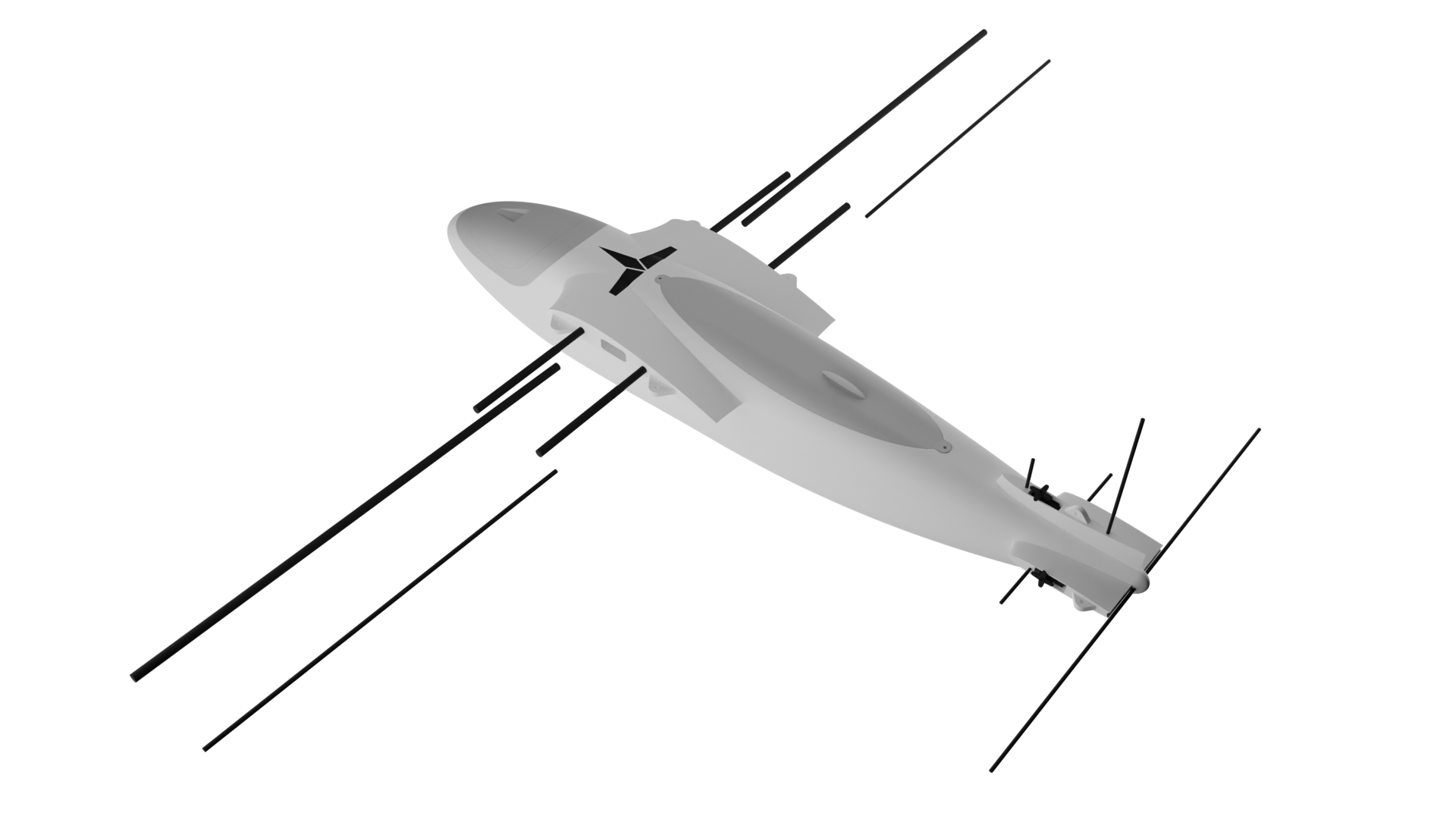

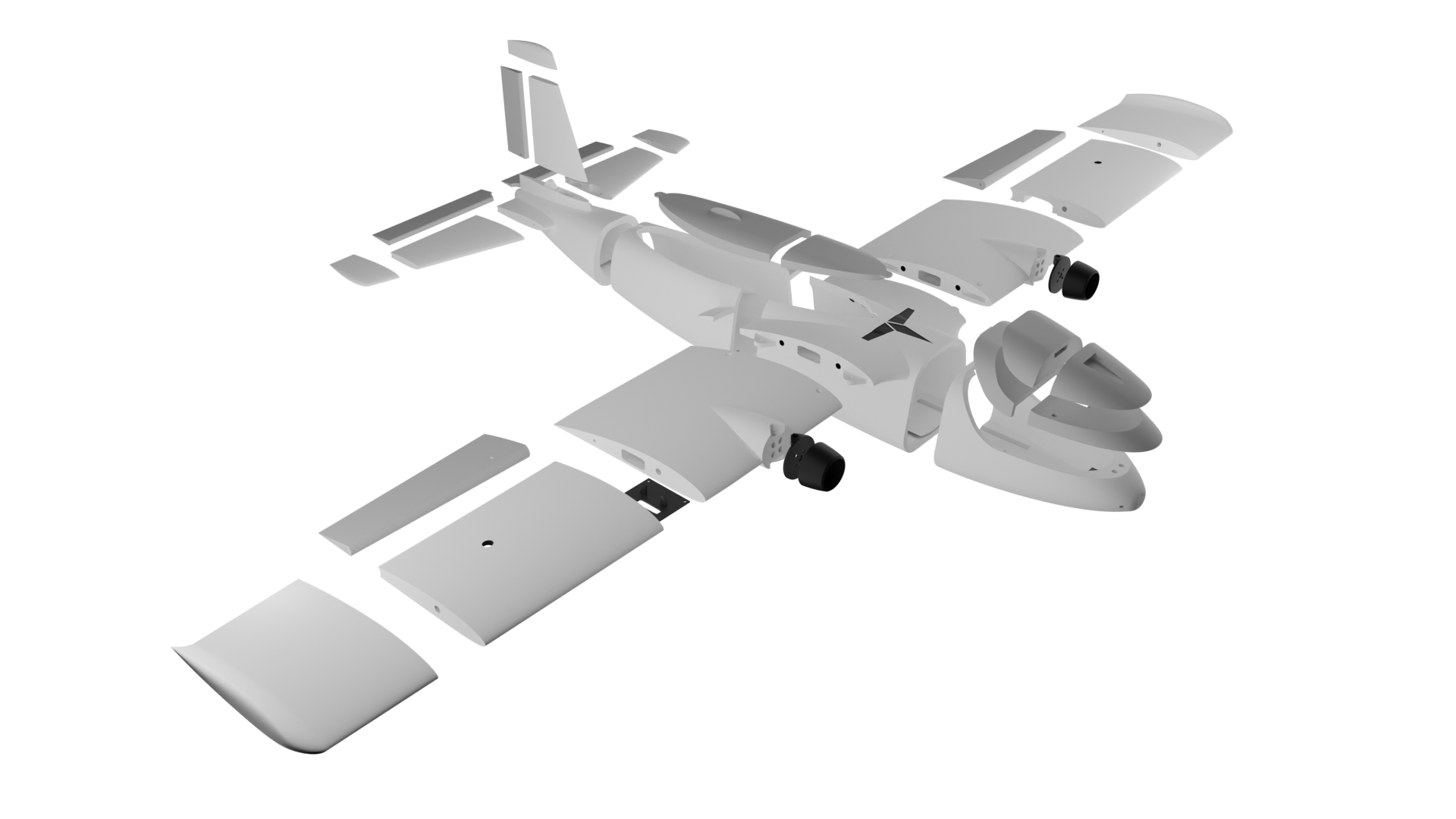

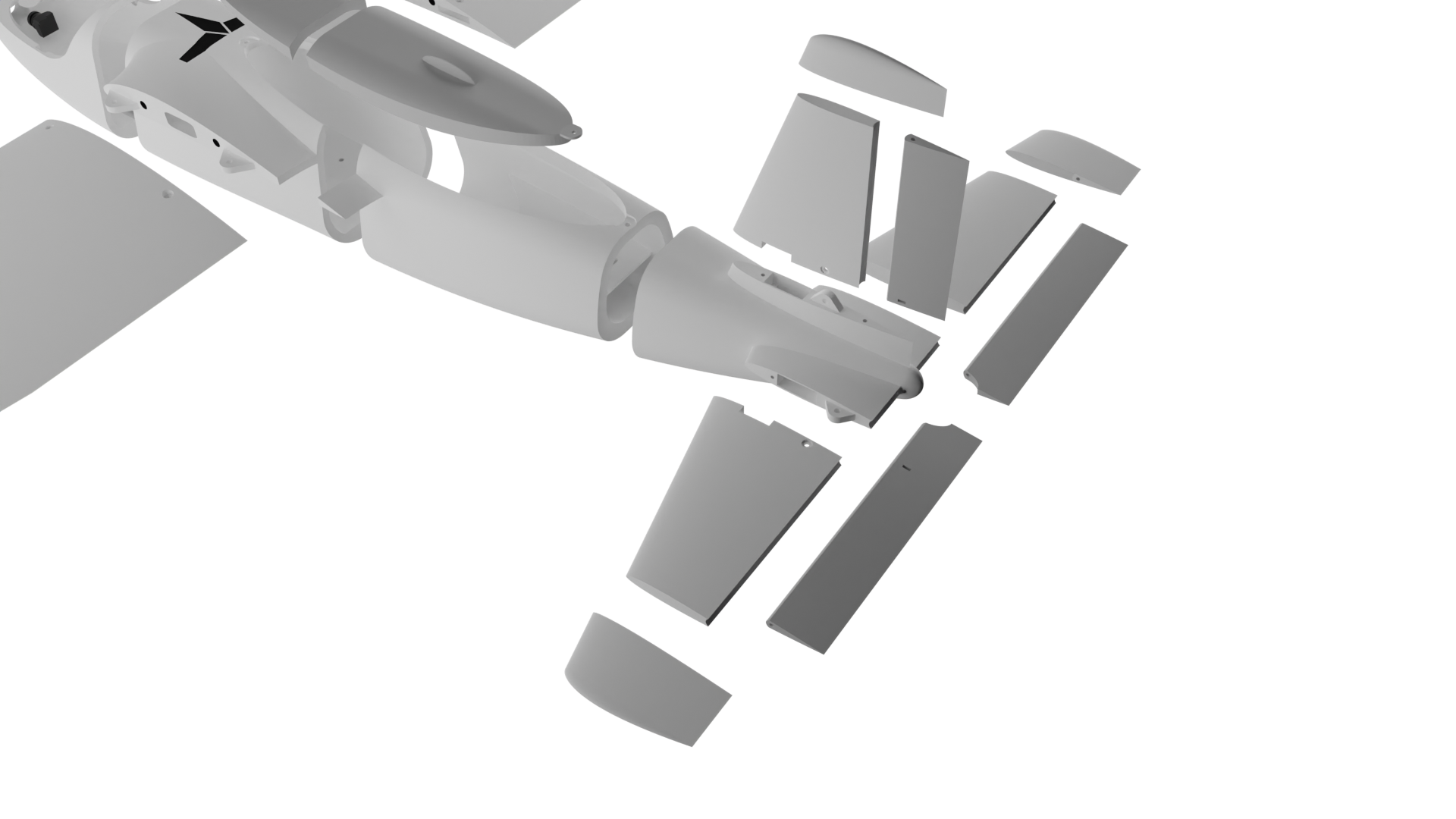

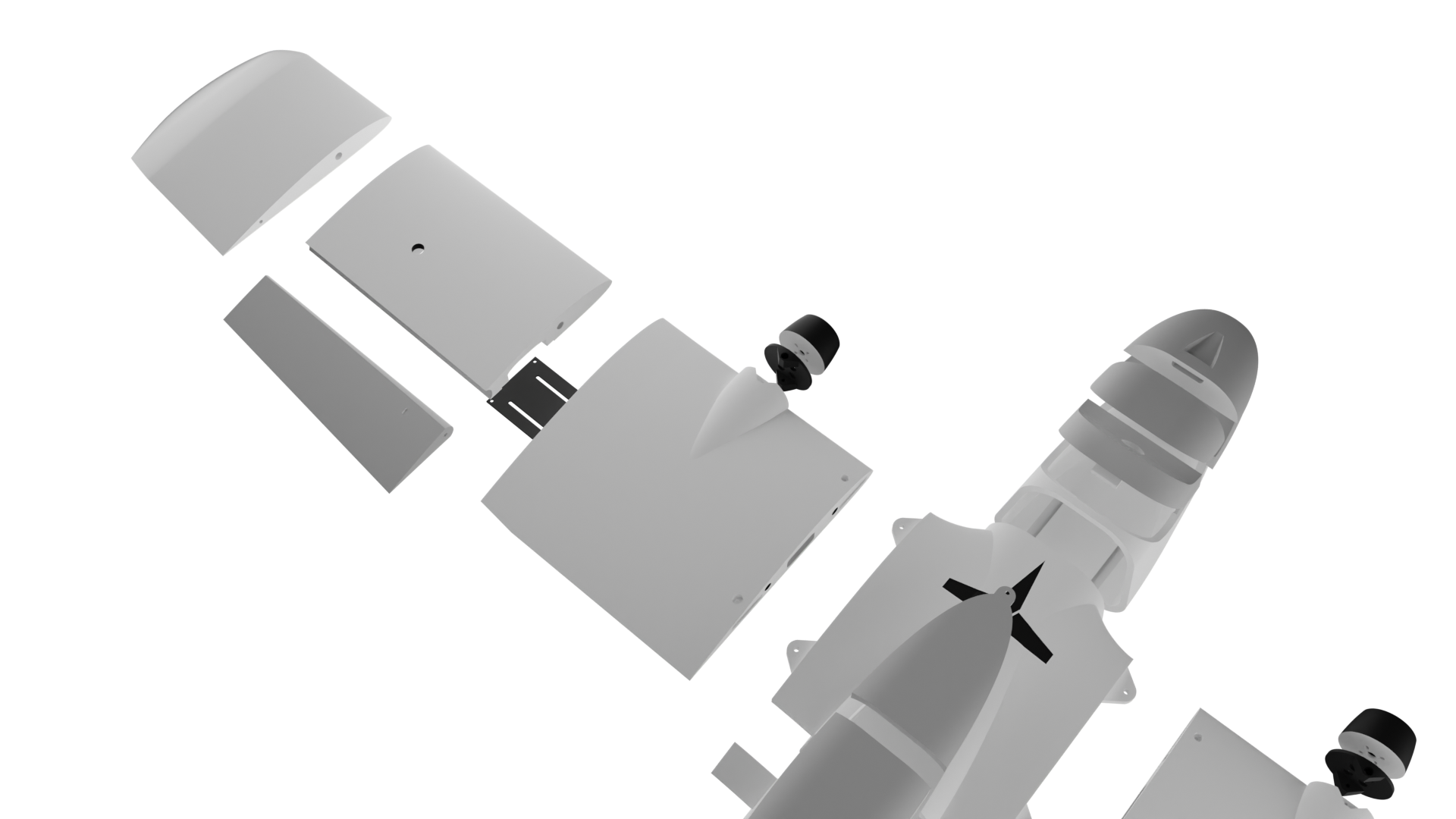

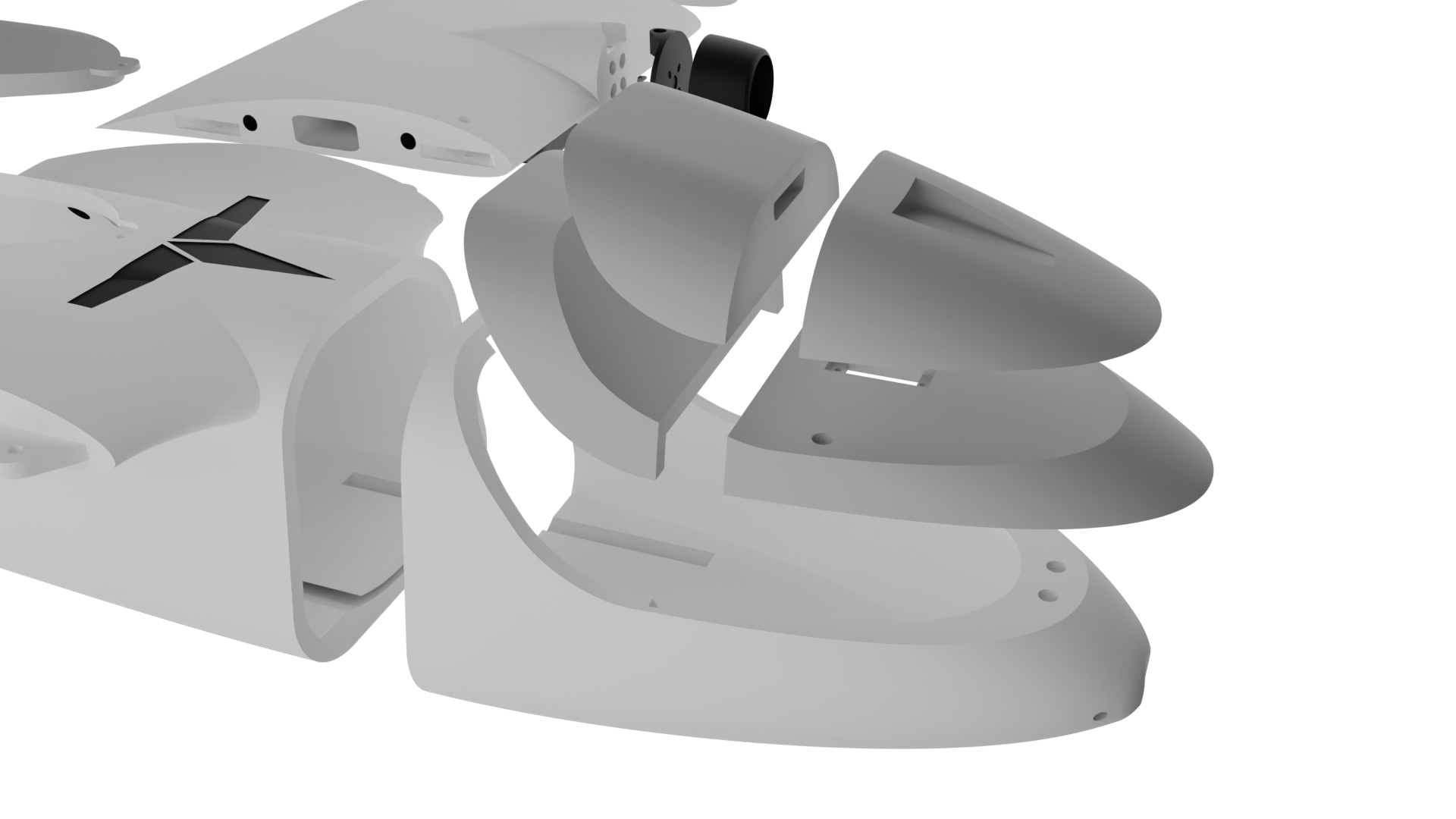

Introducing the Titan Comet, a 1.46m wingspan twin tractor UAV built for the ultimate FPV and mapping experience. The Comet is ultra efficient and can fly for up to 4.5 hours and 260km on one charge. Incredible attention to detail has gone into making Comet lightweight yet structurally rigid. The Comet comes equipped with a double decker FPV deck suitable for action cameras, gimbals, or pan/tilt setups. It’s got enough room in the fuselage to fit your entire arm through the rear hatch or front canopy. Additionally, there’s optional fuselage sections that allow for mounting a mapping camera in the belly and external antennas. The elevator and rudder servos are concealed and serviceable via the removable stabs. The wings are also removable for transport. Just like the Falcon, the wings feature large bays underneath for mounting a VTX or RX (or other high temp equipment) with ample antenna separation. All control surfaces feature nearly 0 gap with rounded leading edges that are sunk into the wings/stabs.

Titan Comet

Introducing the Titan Comet, a 1.46m wingspan twin tractor UAV built for the ultimate FPV and mapping experience. The Comet is ultra efficient and can fly for up to 4.5 hours and 260km on one charge. Incredible attention to detail has gone into making Comet lightweight yet structurally rigid. The Comet comes equipped with a double decker FPV deck suitable for action cameras, gimbals, or pan/tilt setups. It’s got enough room in the fuselage to fit your entire arm through the rear hatch or front canopy. Additionally, there’s optional fuselage sections that allow for mounting a mapping camera in the belly and external antennas. The elevator and rudder servos are concealed and serviceable via the removable stabs. The wings are also removable for transport. Just like the Falcon, the wings feature large bays underneath for mounting a VTX or RX (or other high temp equipment) with ample antenna separation. All control surfaces feature nearly 0 gap with rounded leading edges that are sunk into the wings/stabs.

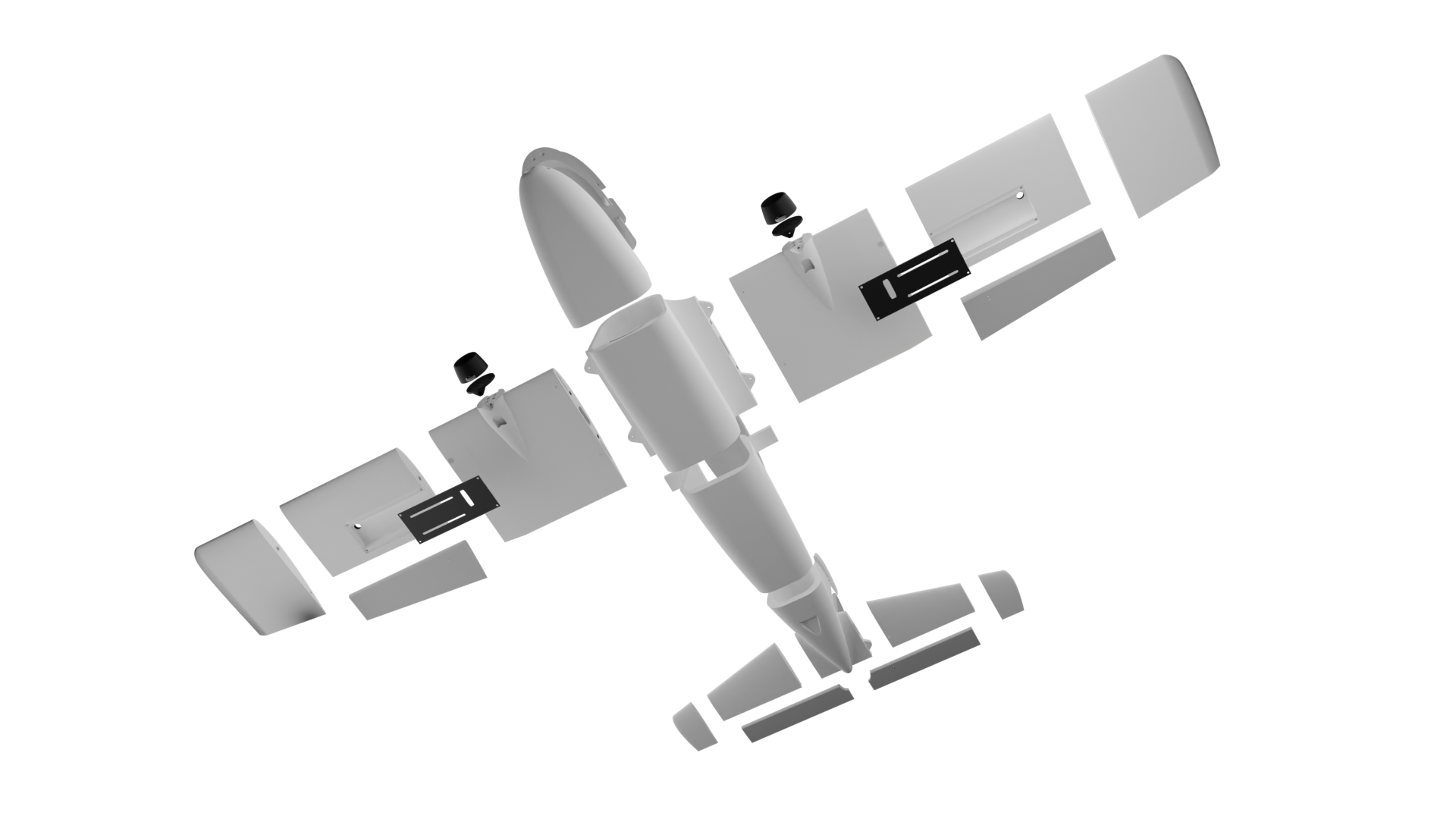

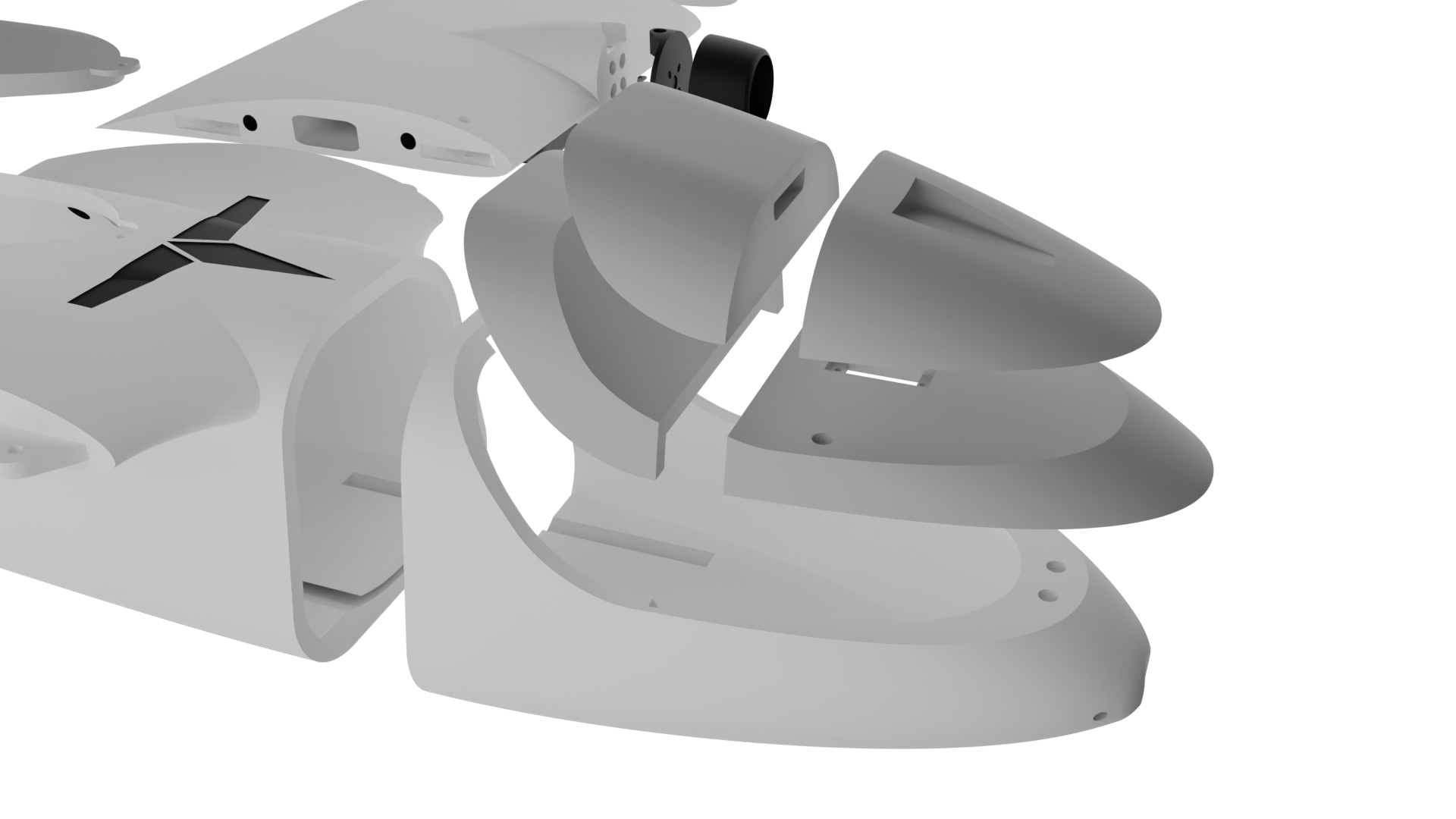

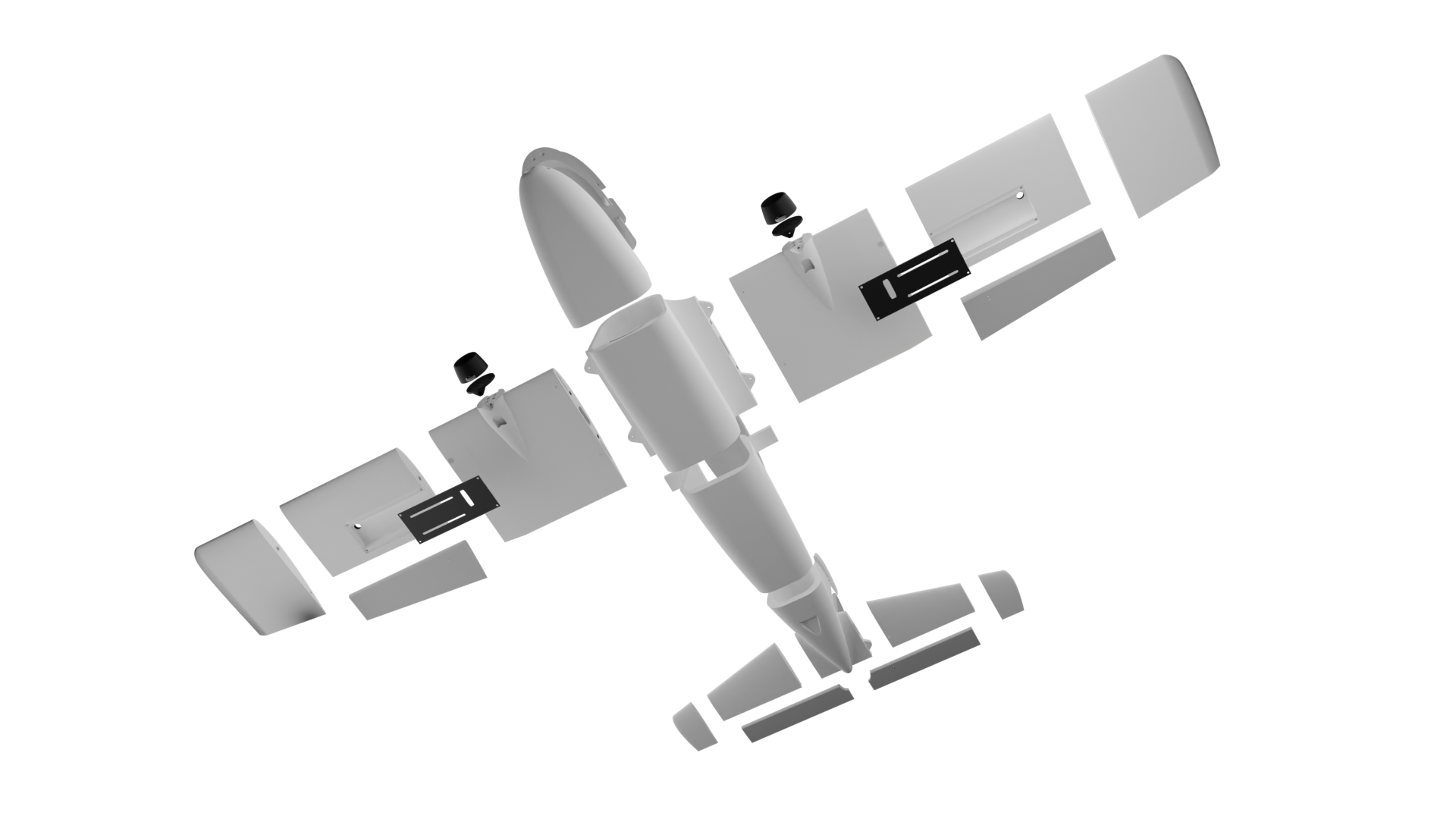

An up close look at the double-decker canopy which allows for mounting various FPV pan/tilt setups or gimbals and action cameras

An alternate nose piece without FPV camera hole is also included

Optional fuselage sections with antenna mounts and mapping camera provisions (2.5” lens) are included

Comet performed flawlessly and produced a cruise efficiency of 1.29wh/km and 84.24mah/km, which is spectacular and surprisingly efficient for a twin motor aircraft

Comet’s CFD simulation results show fantastic results. Born from CFD, Comet was specifically engineered to have ideal flight characteristics, low drag, and a excellent stall characteristics

Spars needed:

(2) 8x500mm (main wing spars)

(2) 8x500mm (wingtip support)

(2) 4x400mm (aileron hinge)

(1) 3x200mm (hstab support)

(1) 3x60mm (vstab support)

(1) 3x200mm (rudder hinge)

(1) 3x500mm (elevator hinge)

Recommended motor & prop:

16-19mm mounting pattern

2212 / 2216 up to 28xx size (ideally 2216)

8-10 inch prop (ideally 9x6)

Recommended electronics:

TBS crossfire / ELRS / Dragonlink

5.8ghz / 1.2ghz video (19x19 camera)

Matek F405-WTE flight controller or similar

Matek M8Q-5883 GPS/Compass or similar

35a BLHeli ESCs (place in the fuselage)

(4) Emax ES08MAII servos

Example battery for fun flying: 10,000mah 4S/6S Lipo

Example battery for medium endurance: 4S3P 21700 15,000mah Li-Ion

Example battery for max endurance: 4S8P 18650 28,000mah Li-Ion

Misc:

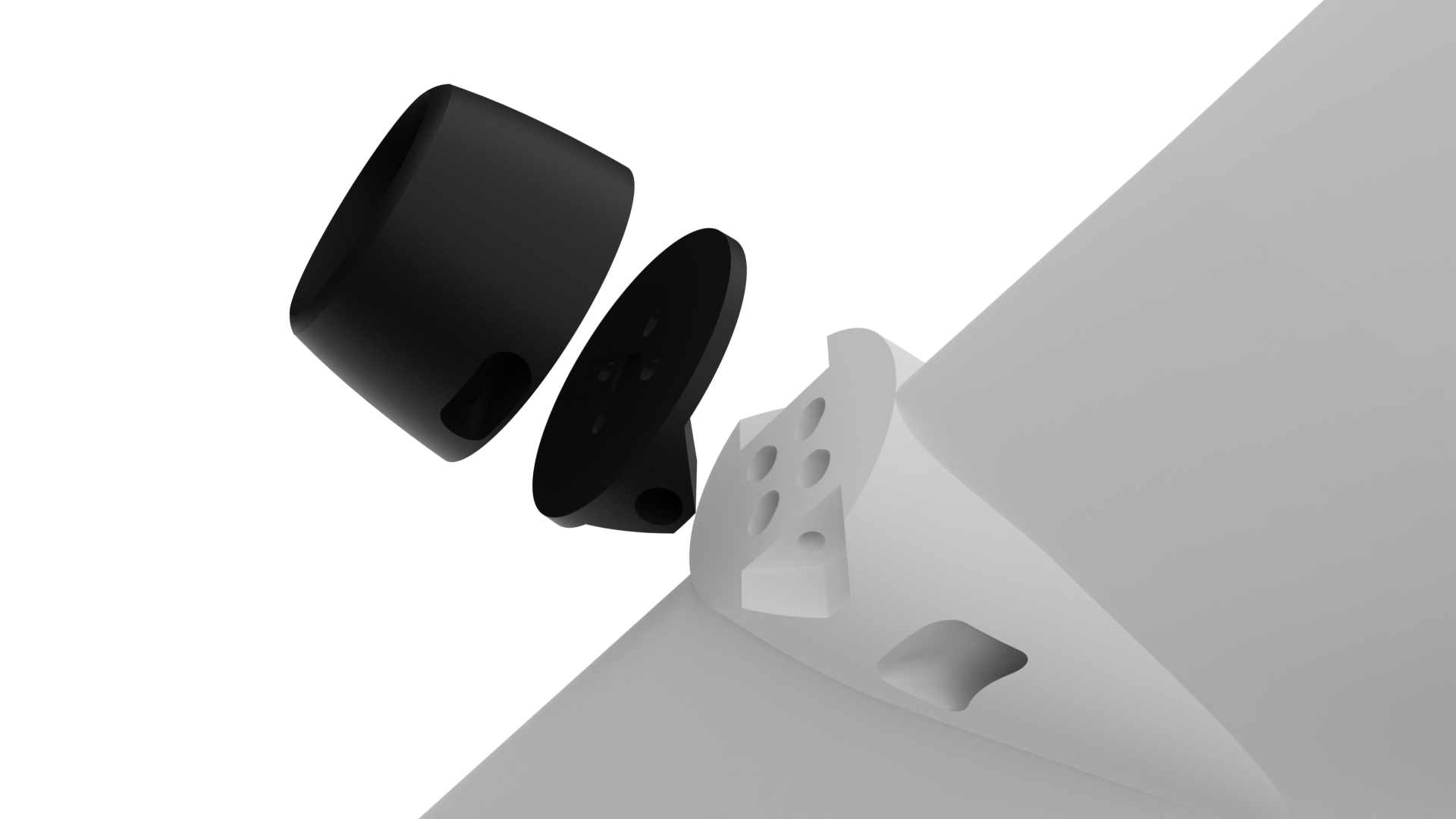

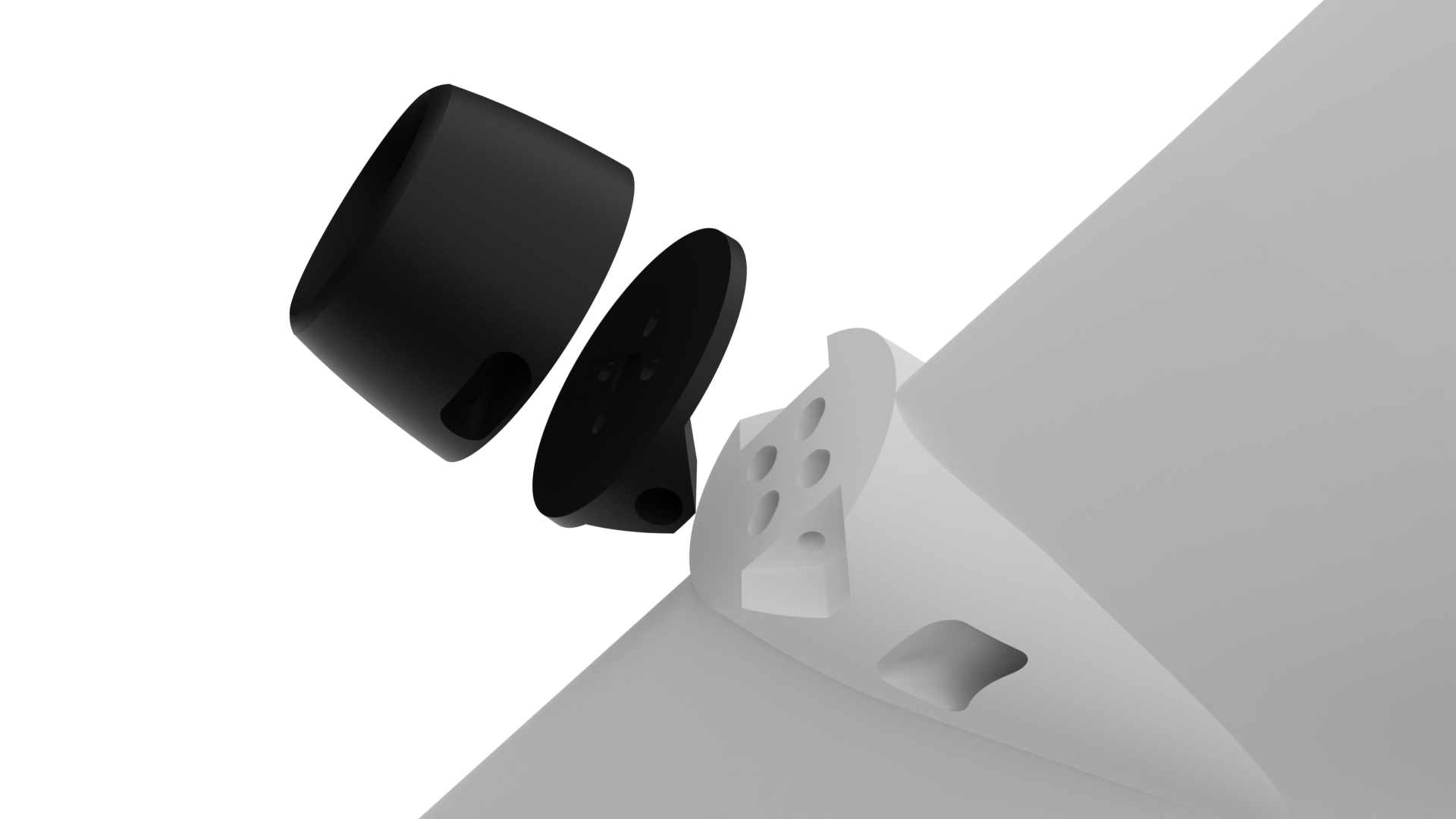

Polycarbonate or other high-temp filament for the motor mount

Medium CA glue

220x220x250 minimum size print bed (Ender 3)

Control horns (this one)

M3 threaded inserts (max 6mm height)

M3 bolts of various sizes

6x3mm magnets

Print settings:

LWPLA parts should be single wall, and 3-4% cubic subdivision for lighter weight. Use best judgement based on each part and its function

High temp (Polycarbonate or PETG) parts (motor mounts and wing bays) should be double wall and high infill (25-100%)

Additional Info:

Give all control surfaces +- 35 degrees or more throw. Flaperons can go down up to 45 degrees

Setup motor rotation such that props rotate inwards towards the fuselage, for added torque roll during differential yaw

Takeoff and landing can be performed with or without flaperons down

CG is marked under the wing, however is very forgiving +- 10mm

Aim for a dry weight of 1.6kg without battery, and maximum takeoff weight of 4kg (feel free to push it past that if you dare). A nice all-up-weight is 2.8kg

Wingspan: 1460mm | Wing area: 3316 cm^2

Apply rubberized tape / duct tape to the belly to guarantee damage-free landings

Licensed under the Creative Commons - Attribution - Non-Commercial license.

Updated STLs 1/8/23

Built in support structure on the belly/floor.

Battery strap no longer cutting through the floor, integrated into the fuselage floor

Updated STLs 4/15/23

25x19 motor mount (thanks to Marco Robustini)

Large motor shroud for 35xx motors

Updated STLs 7/8/24

Spar overlap increased in wing to increase stiffness